Continuous rod inspection was previously reliant on manual visual checks by experienced personnel. These inspections are prone to human error and often fail to provide a complete 360° view of the rod, risking undetected defects and costly premature failures. By adopting EMI, operators can avoid scrapping serviceable rods unnecessarily, reducing work-over costs and improving operational efficiency.

The Lv-EMI™ System is revolutionizing well production by addressing inspection challenges with cutting-edge electromagnetic testing. This non-destructive method uses advanced magnetic flux leakage (MFL) and magnetic flux density (MFD) measurements to provide a comprehensive assessment of continuous rod health.

The Lv-SmartMod™ is compact, field-suitable, and easily fits between the last guide arm and the rod spool. Rubber strippers eliminate excess oil and paraffin, while depth counters pinpoint defect locations in the rod string. The Lv-DAQ™ sends signals to the Lv-Zephyr™ software to quickly interpret signals from the EMI unit, triggering inspector action when defects are detected to aid in generating an inspection report and expedite return to well production.

The Lv-EMI™ System comes in three rugged cases that lock together for transport and deployment. In less than five minutes, the full unit can be set up on location, ready to deliver accurate and repeatable rod inspection without slowing down well-servicing operations.

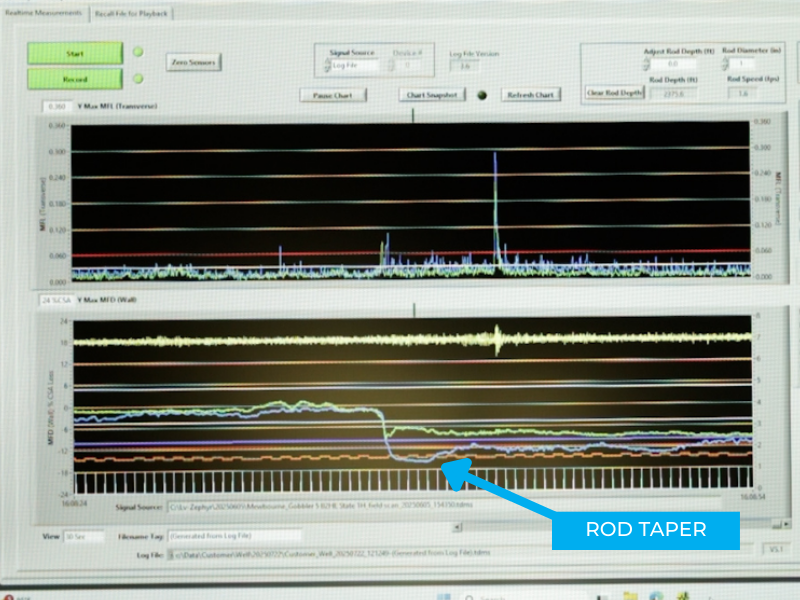

Lv-Zephyr™ Software - The system includes a Lv-Laptop, a robust Durabook Laptop with annual so ware licenses. The Lv-Zephyr Software package interprets signals from the Lv-DAQ™ to trigger inspector actions when defects are detected, simplifying previous processes and making it easier to identify issues or expedite the return to well production. Lv-SmartMod™ - Easily fits between the last guide arm and the rod spool. With quick installation and removal, it ensures seamless operation. Rubber strippers eliminate excess oil and paraffin, while depth counters pinpoint defect locations in the rod string. Lv-DAQ™ - Compact and low-power Lv-DAQ sends signals from the Lv-SmartMod unit to the Lv-Zephyr software. Lv-SmartMod™ Adapter and Cable - The system has everything you need to run the rod, including the Lv-SmartMod Adapter and Cable. Other auxiliary equipment is comprised of the the LV-Sensor Set and Lv-Calibration Coupons.

Compact, portable design – install/remove in under 5 minutes

Lv-SmartMod™ with sensors for various rod sizes

Lv-Zephyr™ Software featuring intelligent calibration and automated defect reporting

Low-voltage operation and durable for field deployment

Decreases ownership cost over the life of the well